PVC Pipe Extrusion Machine (20-1000mm)

What is PVC Pipe Extrusion Machine?

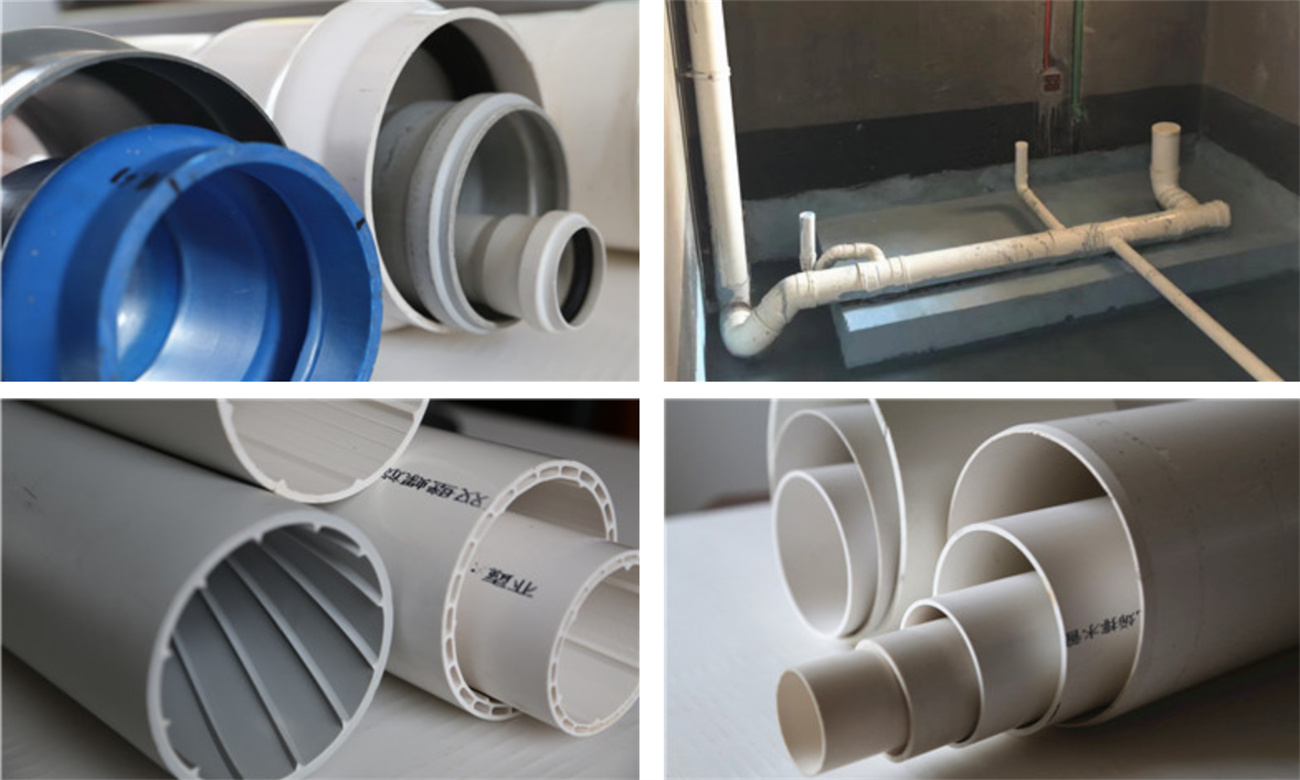

Ф20-1000 series PVC pipe extrusion machine line is mainly used in manufacturing PVC pipes for agricultural and constructional plumbing, cable laying, etc. PVC pipe extrusion line is composed of a conical twin-screw extruder, mould, vacuum calibration tank, haul-off, cutter, and stacker, etc. The extruder and haul-off adopt imported AC frequency control device, vacuum pump and haul-off motors adopt the high-quality brand. The pressure transmitter of the whole production line adopts reliable and stable products. The haul-off methods are two-claw, three-claw: four-claw, six-claw, eight-claw, etc. you may choose saw cutting type or planetary cutting type. PVC pipe planetary cutting machine is fully automatic computer control, it has such advantages of simple operation, reliable property and reached world advanced level. It is additionally attached with the length counter and intensifying device. This PVC pipe extrusion equipment is with reliable performance and high production efficiency.

| Pipe diameter(mm) | 16-63 | 20-110 | 50-160 | 75-250 | 110-400 | 315-630 | 560-1000 |

| Extruder model | 51/105 65/132 |

65/132 | 65/132 | 80/156 | 80/156 | 92/188 | 115/225 |

| length of vacuum calibration tank(mm) | 5000 | 6000 | 6000 | 6000 | 6000 | 8000 | 10000 |

| Puller | 2 claw | 2claw | 3claw | 3claw | 4claw | 6claw | 8claw |

What is the application of PVC pipe extrusion machine?

PVC pipe extrusion production line products are mainly used in producing of PVC pipes with various tube diameter and wall thickness in the aspects such as agricultural, constructional, and cable laying etc.

The specification and size of PVC pipes are Φ 20, Φ 25, Φ 32, Φ 40, Φ 50, Φ 63, Φ 75, Φ 90, Φ 110, Φ 125, Φ 140, Φ 160, Φ 180, Φ 200, Φ 225, Φ 250, Φ 280, Φ 315, Φ 355, Φ 400, Φ 450, Φ 500, Φ 630, Φ 720, Φ 800, etc. The pressure shown on PVC pipe is expressed as nominal pressure, expressed in MPa. The nominal pressure is specified as 0.63Mpa, 0.8MPa, 1.0MPa, 1.25mpa, 1.6Mpa, etc. The minimum diameter pipe of each pressure zone is specified as: the minimum diameter of 0.63Mpa pipe is 63mm, the minimum diameter of 0.8MPa pipe is 50mm, the minimum diameter of 1.0MPa pipe is 40mm, the minimum diameter of 1.25mpa pipe is 32mm, and the minimum diameter of 1.6Mpa pipe is 20mm and 25mm. The pipe length is generally 4m, 6m and 8m, which can also be determined by the supplier and the demander through consultation.

Can PVC pipe extrusion machine line be customized for specific pipe specifications?

Yes, as professional PVC pipe manufacturing machine supplier, we offer customization options to tailor the extrusion line to produce pipes of specific sizes, wall thicknesses, and with various additives for enhanced properties.

What is included in PVC pipe production line?

●DTC series screw feeder

●Conical twin-screw PVC pipe extruder

●Extruder die

●Vacuum calibration tank

●Spray Cooling tank

●PVC pipe extrusion haul-off machine

●PVC pipe cutting machine

●Stacker

●PVC pipe belling machine

Optional Auxiliary machines:

How is the process of PVC pipe extrusion line?

Extrusion PVC pipe process: Screw Loader → Conical twin-screw extruder → Mold and calibrator → Vacuum forming machine → Cooling tank → Haul off machine → Cutting machine → Discharging Stacker

Flow Chart of PVC pipe extrusion machine line:

|

No |

Name |

Description |

|

1 |

Conical twin-screw PVC pipe extruder |

It is mainly used for the production of PVC pipes. |

|

2 |

Mould/Die |

Single-layer extrusion dies or multi-layer extrusion dies can be selected to produce single-layer or multi-layer pipes. |

|

3 |

Vacuum Calibration tank |

Optimum stainless steel vacuum calibrator and pipe works. Dual water cycle system with independent filter prevents the nozzle from being blocked. Quick response vacuum control system guarantees the reliable vacuum state. High efficiency spray cooling guarantees the quick shaping under vacuum condition. Automatic water temperature and level control. Single chamber and/or double chamber vacuum calibrator are available according to the article requirement. |

|

4 |

Spray Cooling tank |

Multiple spray cooling tanks can be used to achieve better cooling effect. Stainless spray cooling tank (trough) and pipe works. Rapid and even pipe cooling is realized by the rationally distributed nozzle and the optimized dual-circuit water pipe with filter. Automatic water temperature and level control. Both stainless steel spray cooling tank and the visible stainless steel spray cooling trough can be available according to customer’s requirement. |

|

5 |

PVC pipe haul-off machine |

Caterpillar with AC servo motor realizes precise synchronization driving. With pneumatic flexible clamping, the upper caterpillar can adapt per the pipe specification variation and keeps good contact pressure with the pipe; the lower caterpillar can be electrically adjusted to the required haul-off position per the pipe specification. High friction rubber pads connects with the chain. Haul-off unit with 2, 3, 4, 6, 8, 10, 12, 16 caterpillars |

|

6 |

PVC pipe cutting machine |

Hydraulic fluctuating blade advancing method, special blade/saw structure suitable for cutting pipes of big wall thickness, smooth cutting. Simultaneous PVC cutting and chamfering. Provide saw cutting machine & planetary cutting machine options. PLC synchronization control. |

|

7 |

PVC pipe belling machine |

To make socket at pipe end which is easy for pipe connection. There are three types of belling type: U type, R type and square type. |

|

Note: Machines can be customized according to customer requirements. Our company make the most suitable machine configuration according to customer requirements. |

||